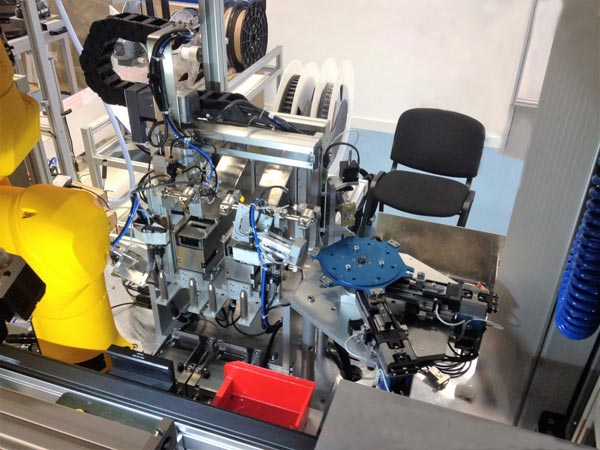

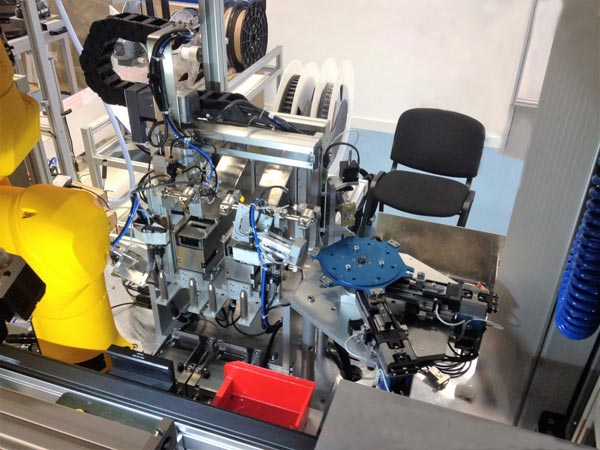

OMCH sensor production line has been designed to meet the requirements of our customers' high-quality and low-volume production. We provide an extensive range of products in high quantities, tailored to meet each customer's specific needs.

Standardized materials and strict quality control guarantees high speed production and meets the demand in the market.

The OMCH Production Line is used to produce different types of sensors. The main components include the unique sensor PCB-this is the core parts, body, front and back cap, glue, wire etc.

To provide professional solutions

Specialized solutions for automation equipment

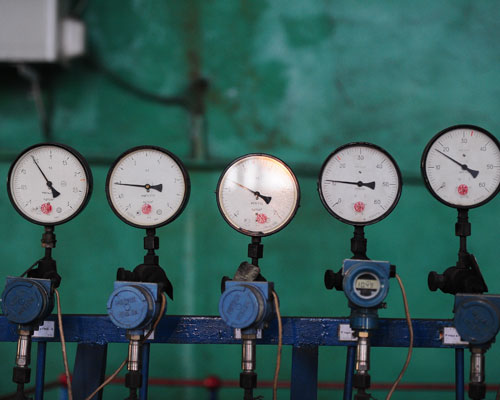

Our proximity switches are used in different industries

The proximity sensor switch is widely used in valve control. Oilfields, nuclear power plants, food processing plants and beverage manufacturers all need to have valve positions inspected to help staff confirm the state of the valve opening and closing and the size of the opening range.

Sensor technology in the medical industry has a lot of play, now, sensors in cancer treatment, non-invasive detection, and other areas have shown great potential.

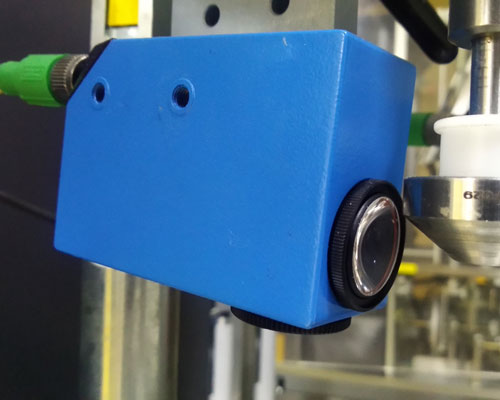

The color mark sensor strictly corresponds to the spectral composition of the target irradiation, once the label is detected, the signal is immediately sent to the back-end PLC system, at this time can be followed by positioning, cutting and other processing.

Relying on photo sensor switch and proximity switch to obtain production information for the food industry has been the trend for modern food processing companies. Integrated circuit detectors have been used extensively in foreign food processing plants and this technology detects the time of spoilage of food.

The capacitive proximity switch is made by using the principle of changing the electrical capacity of the object under test by approaching it.

Inductive proximity sensor switch is usually used in the automobile industry, it can monitor the running status of the whole production line in real-time.

Was founded in the spring of 1986. At that time, there were only three people, but we were already working on inductive proximity switch, photoelectric switch. We also started our own brand, “OMCH”. After 3 years of development, we have become an excellent inductive proximity sensor supplier.

Our customers are satisfied with the quality of the proximity sensors we produce

1)The working principle of optical coupler is that the […]

Read moreSmart cities are a dream that can impact the lives of b […]

Read more