Introduction

Sensors are an integral part of any automation system to allow detecting the presence of objects. When considering photoelectric sensors, there are three types of sensors: thru-beam, reflective and diffused. There is an improved version of diffuse mode sensors called ‘background suppression sensors’. In this article, we’ll be talking about background suppression sensors and how they operate.

What is a Background Suppression Sensor?

Before we talk about background suppression, let’s refresh our knowledge on photoelectric sensors in general. Photoelectric sensors use optical signals to detect the presence of an object. There are three major types of photoelectric sensors: through-beam (thru-beam), retroreflective and diffuse-mode.

Photoelectric Sensor Types

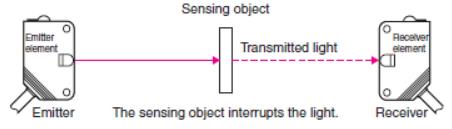

Through-beam sensors are the simplest form of photoelectric sensors. They have a separate transmitter and receiver unit placed facing each other. When an object obstructs the laser/light beam, the absence of the light beam triggers the receiver. This signal can be used to detect whether the object is present or not.

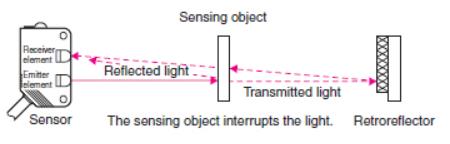

Retro-reflective sensors have both the transmitter and receiver built into the same unit. A special type of reflector is placed across the beam that reflects the transmitted beam in a specific way back to the transmitter. When an object is placed across the beam, the reflected beam is diffused and the amount of light reflected changes. This allows the sensor to detect even transparent objects due to the refraction present in the object itself. Retroreflective sensors rely upon the interruption of the beam to detect the object.

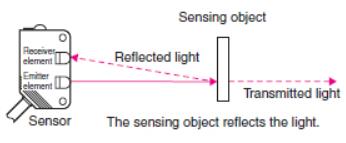

Diffuse-reflective sensors are the third type of photoelectric sensors. They rely on the object itself to reflect the light beam back to the sensor. Diffuse reflective sensors do not need a reflector due to this reason.

Standard diffuse mode sensors use the amount of reflected light to detect an object.

Issue with Diffuse Mode Reflection

In many cases, diffuse mode reflective sensors offer a calibration option where the sensing distance/range can be adjusted. However, since the sensor relies on the object to reflect the beam, any shiny object across the beam other than the object can also reflect the beam. This causes false triggers and can cause significant problems.

For example, a standard diffuse mode sensor set to detect a reflective object within 15 inches can falsely detect another object that is also highly reflective which can be as far as 6 feet away.

Background Suppression Sensor

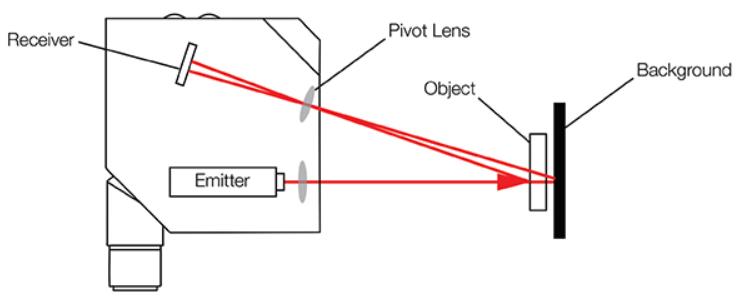

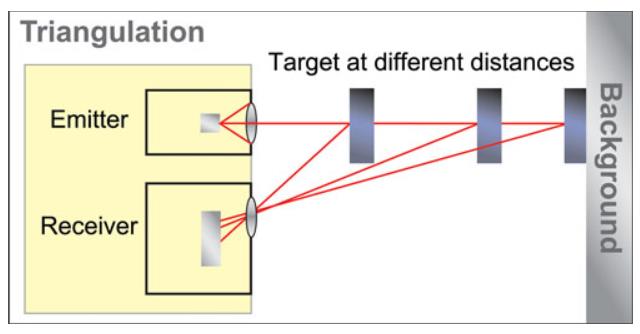

Background suppression sensors help mitigate the problem discussed above. It is a variation of diffuse mode reflective sensor that uses the ‘triangulation principle’. Unlike a regular diffuse mode sensor which measures the amount of reflected light, background suppression sensors measure at which angle the reflected light falls on the sensor.

Background Suppression Sensor Working Principle

Background suppression sensors are similar to diffuse mode sensors. They have both the emitter and receiver embedded into the same housing and rely on the object being detected to reflect the beam back.

When an object is placed in front of a background suppression sensor, the beam is reflected back at an angle. This angle changes depending on the distance from the sensor to the object. When the object is closer, the angle is greater than when it is far away.

Adjustable sensor types are available in two types: mechanical or electrical. In the mechanical type, the sensor can be calibrated using a screw to adjust the point of interest to detect the object. In electronically calibrated models, the sensor has a button to ‘learn’ the type object and the background.

How do the Background Suppression Sensors Suppress the Background?

Background suppression sensors have a clever mechanism to measure the relative position of the object with respect to the background. This makes this type of sensor highly immune to backgrounds that have similar reflective properties as the object being detected.

Unlike fixed-focus or sharp-cut-off type sensors, which do not consider the background at all, background suppression sensors can actually distinguish the object from a similar textured, coloured background.

In a background suppression sensor, there is a single emitter and multiple receivers that are sensitive to the emitted light. This can also be multiple regions of the same sensor in electronic background suppression type.

When there is no object in front of the sensor, there can be two scenarios.

- The emitted beam is reflected by the background

- The emitted beam is not reflected by the background

If the beam is not reflected by the background, the sensor concludes that the distance to the object is infinite and does not activate its output. If the background is reflective, the reflected beam falls on a particular area of the receiver (on the top area of the sensor in the above picture).

The sensor is calibrated/tuned to disregard this region of the sensing element. When an object is placed in front of the sensor, the reflected beam angle changes. This causes the beam to shine on a different part of the sensor (or another sensing element in some models) that the sensor can distinguish as a detection.

In the above picture, note how the closest position to the sensor causes the largest angle in the reflected beam. The angle decreases as the object moves away from the sensor.

Mechanical Background Suppression vs. Electronic Background Suppression

In order to optimize cost and performance, there are two types of background suppression sensors – mechanical and electronic types. Electronic type has a single, large sensor where software processing is done to set and determine the object detection region. This is achieved by a special sensor called Position Sensitive Device (PSD). Software processing of the signal allows additional filtering to be done on the signal to reduce artifacts from heavy vibrations. This is one of the advantages of electronic BGS sensors.

On mechanical types, there are two or more sensing elements to provide higher accuracy, better optical performance and a sharper cutoff range with temperature stability. There is also an optics system to allow fine tuning, which adds to the size of the sensor unit.

Conclusion

In this article, we discussed background suppression sensors. These sensors are very useful in detecting material that are reflective placed in similar coloured/textured backgrounds. Pepperl+Fuchs is one of the industry leading manufacturers who manufacture diffuse mode photoelectric sensors that have background suppression.