Introduction

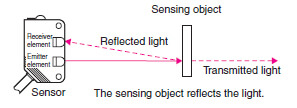

Diffuse-reflective photoelectric sensors are a type of optical sensor that are commonly used in industrial automation applications. They have a built-in light emitter and a receiver. These sensors detect the emitted light bouncing off of an object, and thereby determines if an object is present.

What is a Diffuse Photoelectric Sensor?

A diffuse photoelectric sensor, also known as diffuse-reflective sensor is an optical proximity sensor. It uses the principle of reflection to detect objects in its sensing range.

The sensor has a light source and a receiver housed in the same package. The light beam is emitted towards the target/object and reflected back to the sensor by the target.

The object itself acts as a reflector, eliminating the need for a separate reflector unit. The intensity of the reflected light is used to detect the presence of the object.

Diffuse Photoelectric Sensor Working Principle

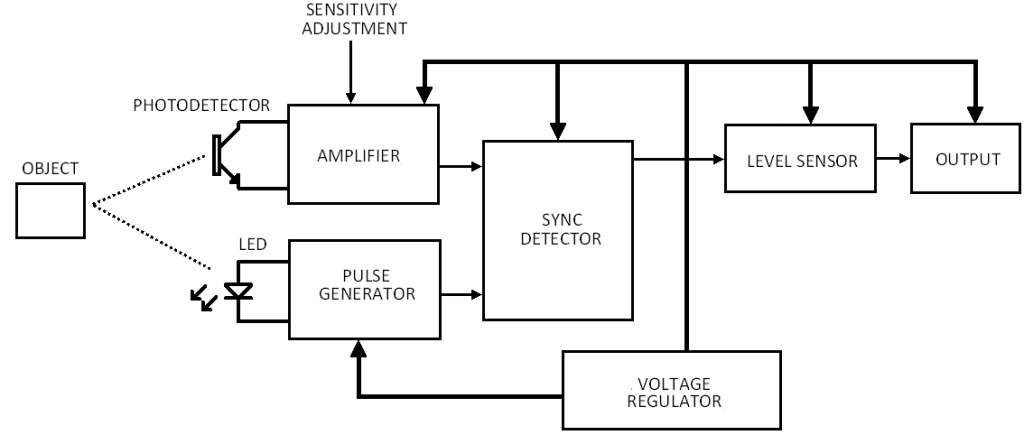

Diffuse photoelectric sensors, like every other photoelectric sensor, have built-in circuitry to modulate, emit, receive and demodulate the light beam and control the output. They have both the emitter and receiver elements built into the same housing.

A photoelectric sensor, in general has a few circuits inside:

- Modulator and Amplifier

- Transmitter and Receiver

- Detector Amplifier and Demodulator

- Output

Modulator and Amplifier Stage

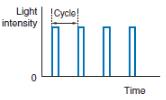

This stage generates a signal to rapidly turn the LED on and off. The signal typically has a shape of a square wave.

The amplifier stage uses the signal from the modulator stage and drives the LED. Some sensors do not have a modulator stage and outputs a direct beam. These tend to have a higher range, but are more prone to interferences caused by external light sources.

Transmitter and Receiver Stage

The transmitter is often an LED due to its lower power consumption and switching speed. The emitted light is in the visible light and the infrared wavelength range. Red LEDs are the most common among the visible light types.

To receive the signal, a photodiode/phototransistor is used. For pulsating emitter type, this phototransistor is spectrally coupled with the emitter LED’s wavelength. This ensures that the phototransistor allows more current to flow when it receives the light that falls in the emitter LED’s wavelength.

Detector Amplifier and Demodulator Stage

The received signal is amplified and further conditioned by filtering and smoothing. The receiver circuit also works in sync with the transmitter, reducing further chances of external interruptions.

This helps the sensor to reject any unwanted light beams emitting at different frequencies that are directed towards the sensor.

Output Stage

The output stage receives the conditioned signal from the demodulator and switches the output. This can be sourcing or draining for a PNP/NPN type sensor, or simply activating a normally open or normally closed contact for a relay output type sensor.

What is the Difference Between Diffuse and Retroreflective Sensors?

The main difference between the two is how they detect the objects. Diffuse-reflective sensors rely on the reflection from the object. The beam has to be reflected by the object for the sensor to detect it. Retro-reflective sensors rely on the interruption to an already existing, reflected beam.

The sensor constantly monitors the reflection of the light emitted from itself. Once an object obstructs the reflected beam, the sensor detects that the object is present.

Diffuse-reflective sensors do not require a special reflector as it relies on the object to reflect the beam. This makes the diffuse sensors easy to install and configure. The retro-reflective type needs a special reflector placed across the beam.

There are both advantages and drawbacks in each type. Retro-reflective sensors can detect pretty much any material, transparent or translucent but have a dead-zone at extremely close distances.

Diffuse-reflective sensors can only detect translucent/solid objects, but do not have a dead-zone.

Retro-reflective sensors have a range from several centimeters to several meters while diffuse sensors have only about 10-35mm of range. Both have relatively simple wiring and are relatively easier to mount and calibrate.

Conclusion

Diffuse-reflective sensors can be seen in applications where detection of parts, boxes and other solid material is required. They work best with glossy/solid materials like metal and paper. There are also other types of photoelectric sensors such as retro-reflective sensors and through-beam sensors that can be a replacement for diffuse-reflective sensors. Selecting a correct sensor type greatly improves the system’s accuracy and performance.