Introduction

Photoelectric sensors are the type of sensors used to detect objects based on a variety of optical properties. Photoelectric sensors are made of an emitter light and a receiver element.

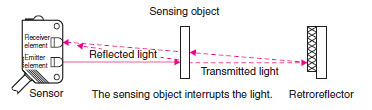

The sensor can detect the interruption to a reflected light beam, and decide if an object is present or not.

In this article, we’ll be talking about retro-reflective sensors, which belong to the photoelectric sensor family. Let’s see what retro-reflective sensors are, what they are made of and how we can use them to detect objects.

What is a Retro-reflective Sensor?

A Retro-reflective sensor is a type of photoelectric sensor, which uses the interruption of a reflected light beam to detect objects. There are two main types of retro-reflective sensors:

- Standard retro-reflective sensors

- Polarized retro-reflective sensors

Both types of sensors have the light beam emitter and detector/receiver element built into the same housing. The emitted light beam is reflected by a retroreflector back to the sensor.

When an object is placed between the sensor and the reflector, it interrupts the beam. The absence of the light beam causes the sensor to change its output signal.

Retro-reflective Sensor Working Principle

As mentioned above, retroreflective sensors have both emitter and the receiver built into the same housing. A separate reflector unit is placed to reflect the beam back to the sensor.

When an object enters into the region between the reflector and the sensor, it obstructs the light beam. This interruption causes the light beam to diffuse, and the sensor detects the change. It then causes the output to change.

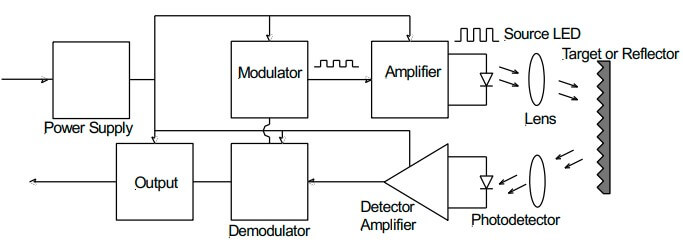

A photoelectric sensor, in general has a few blocks of circuitry inside:

- Modulator and Amplifier

- Transmitter and Receiver with Target/Reflector unit

- Detector Amplifier and Demodulator

- Output

Modulator and Amplifier Stage

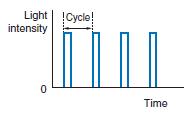

In this stage, the modulator circuit generates a pulsed signal. This is often a square wave that rapidly turns on and off.

The amplifier amplifies this signal and produces enough current to drive the emitter LED. The reason to use a pulsing light beam is to reduce external interference caused by other light sources.

But there are sensors that use non-modulated light. Sensors with non-modulated light beams have longer range, but are susceptible to coherent light and external light interference.

Transmitter and Receiver with Target/Reflector unit

Almost all the photoelectric sensors use LEDs as transmitters/emitters due to the speed and low power consumption. The detector consists of a photodetector/photosensor.

Both transmitter and receiver have lenses to filter and direct the light beam. The transmitted light pulses are reflected by the retroreflector and picked up by the photodiode.

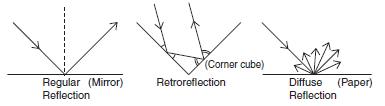

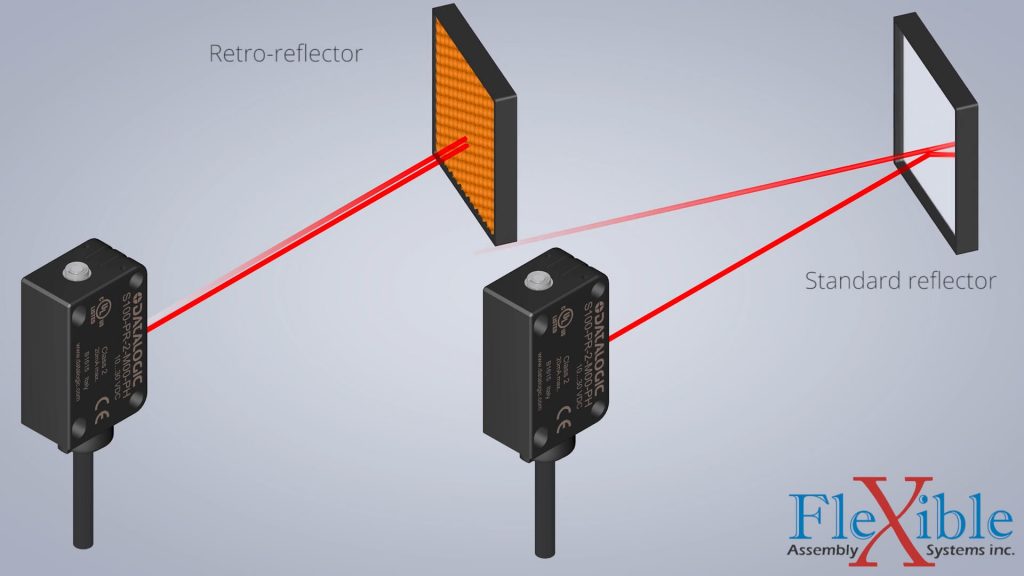

Regular Reflection vs. Retroreflection

A standard reflector like glass reflects light at an angle equal to the incident angle of the light beam. Whenever the reflector is tilted even by the slightest bit, the reflected light beam can be directed elsewhere other than the sensor.

Retroreflectors use corner-cubes, which are made of 3 individual reflective surfaces. They are perpendicular (90 degrees) to each other. They can direct the reflected light back towards the emitted light beam even when the reflector is placed at an angle. This is called ‘retroreflection’.

With the use of a retroreflector, it can be offset or tilted upto 10-30 degrees, and the sensor will still be able to detect the reflected beam.

Detector Amplifier and Demodulator

This stage amplifies the signal from the photodetector and demodulates the received signal. It outputs a control signal to the output stage to switch the output HIGH/LOW.

Output Stage

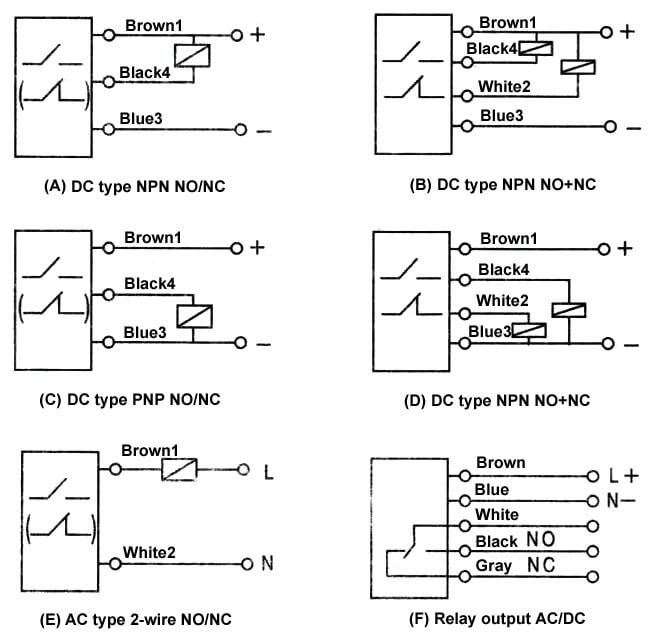

The output stage consists of the final control element to switch the output. This can be a transistor based circuit for NPN/PNP type sensors, or a relay output. Typically, this stage also consists of additional protection such as short circuit protection and reverse polarity protection diodes.

This type of photoelectric sensors use the principle of retroreflection in their sensing mechanism. A retroreflector can reflect a light beam right back to its source, independent of the angle of the reflector.

This helps to calibrate/align the sensor as the sensor does not need to be perfectly perpendicular to the reflector.

Regular Retro-reflective Sensors vs Polarized Retro-reflective sensors

Regular retroreflective sensors can detect almost all objects. But they have trouble detecting shiny objects like polished surfaces or mirrors. A standard retro-reflective sensor cannot detect such objects as they can be ‘fooled’ by the shiny object by reflecting the emitted beam back to the sensor.

A polarized retro-reflective sensor expects the light beam to be polarized by the reflector by 90 degrees. If the reflected beam is 90 degrees polarized, the sensor knows that there is no object.

But when a reflective object enters between the sensor and the reflector, the reflected beam is not polarized and the sensor can thereby detect the object. The only object that can disrupt these sensors’ functionality are retroreflectors.

Retro-reflective Sensor vs Diffuse-reflective Sensor

The main difference between these two types is the reflection method. A diffuse-reflective sensor expects the light to be reflected by the object while retro-reflective sensors expect the light beam to be interrupted by the object to detect it.

Retro-reflective sensors also need a dedicated retroreflector to function.

Diffuse-reflective sensors do not need a reflector as the object to be detected acts as the reflector itself.

This makes diffuse-reflective sensors easier to mount. However, since the detection is based on the reflected light by the object, the physical conditions like color and texture of the object directly affects the sensing performance.

Retro-reflective sensors are less susceptible to conditions like color and angle of the object being sensed. They can be used in applications such as detecting transparent objects like glass. However, retro-reflective sensors have a dead-zone at extremely close distances.

Both the sensors have several centimeters to several meters of sensing distance, have simple wiring and are relatively easier to mount.

Retro-reflective Sensor Application

Retro-reflective sensors find their applications in many industries like automotive, material handling, machine engineering, food and beverage and access control systems.

These sensors are used in assembly lines to provide precision positioning for robotic arms to grab them. The polarized version of retroreflective sensors make the sensor immune to glossy finishes in parts such as bodywork.

In applications such as stacker cranes in warehouses, photoelectric sensors like retro-reflective sensors are coupled with other enhancements like optical data couplers. This enables the stacker cranes to precisely position/retrieve goods and read the content on the barcodes wirelessly.

Elevators also use retro-reflective sensors to detect the position of the doors and the elevator itself to ensure maximum reliability and performance.

Retro Reflective Sensor Setup

Retro reflective sensors are available in two types: dark-on (NC) and light-on (NO). The dark-on type turns the output on when an object is placed between the sensor and the reflector. The light-on type turns the output on when there is no object present.

This is easier to memorize than Normally Closed (NC) or Normally Open (NO). Some sensors have both configurations while other may have a selector switch to select the mode of operation

Below are the typical wiring diagrams for different types of retro-reflective sensors.

There are two LEDs on photoelectric sensors. A green LED to indicate power, and an orange/red LED to indicate the detection.To calibrate a retroreflective sensor, there are two options: teach-in button or a potentiometer.

To calibrate a sensor with a potentiometer, set up the sensor with its reflector and turn the potentiometer until both the LEDs turn off. Adjust the potentiometer until the green LED stays on when there is no object, and both LEDs light up when the object is present.

FAQ on Retro-reflective Sensors

Q: My standard retroreflective sensor is giving me a false reading when detecting a shiny metal as the target. How can I correct this?

A: This is a common problem with standard retroreflective sensors. Selecting a polarized retro-reflective sensor with a corner-cube retro-reflector will eliminate this problem.

Q: I am looking for a retroreflective sensor that is capable of detecting a clear glass bottle on a conveyer for a counting application. What would be the best option?

A: A polarized retro-reflective sensor with clear object detection will work best for such applications. These sensors will also have no dead-zone, which will be advantages in most cases.

Q: What is the best type of reflector to use with retroreflective sensors?

A: Corner-cube retroreflectors are compatible with all types of retro-reflective sensors in most cases. However, polarized retro-reflective sensors must use corner-cube style reflectors to ensure their peak performance.

Q: Are there any reflector options for extreme temperatures?

A: There are reflectors that can withstand high temperatures from 120 to 500 degrees Celsius. For the use in extremely low temperatures, there are reflectors that come equipped with built-in heating elements to prevent fog/ice buildup.

Does a Retro-reflective Sensor Need a Reflector?

The simple answer would be yes. However, this depends on the application of the sensor. A retro-reflective sensor can technically be used in place of a diffuse-reflective sensor if the object being detected is itself a retroreflector or alike.

The configurable light-on and/or dark-on configuration of the sensor makes this approach easier.

However, to ensure highest accuracy, the use of a reflector is vital. On the other hand, polarized sensors do not work at all without a polarizing retro-reflector.

Conclusion

In this article, we discussed the retro-reflective sensors and their principle operation, along with their applications. Optical sensors in general are a good choice to detect objects without contact, and have a higher sensing range than other sensor types.

Selecting a proper photoelectric sensor type for your application will greatly increase the sensing accuracy and will provide a clean output with minimal false triggers.