In industrial environments such as manufacturing and heavy equipment handling, there are ‘keep-out’ zones. These zones are specially marked with bright colours to indicate limits to prevent people from entering. They can contain hazardous substances, involve the movement of heavy machineries and other potentially harmful equipment.

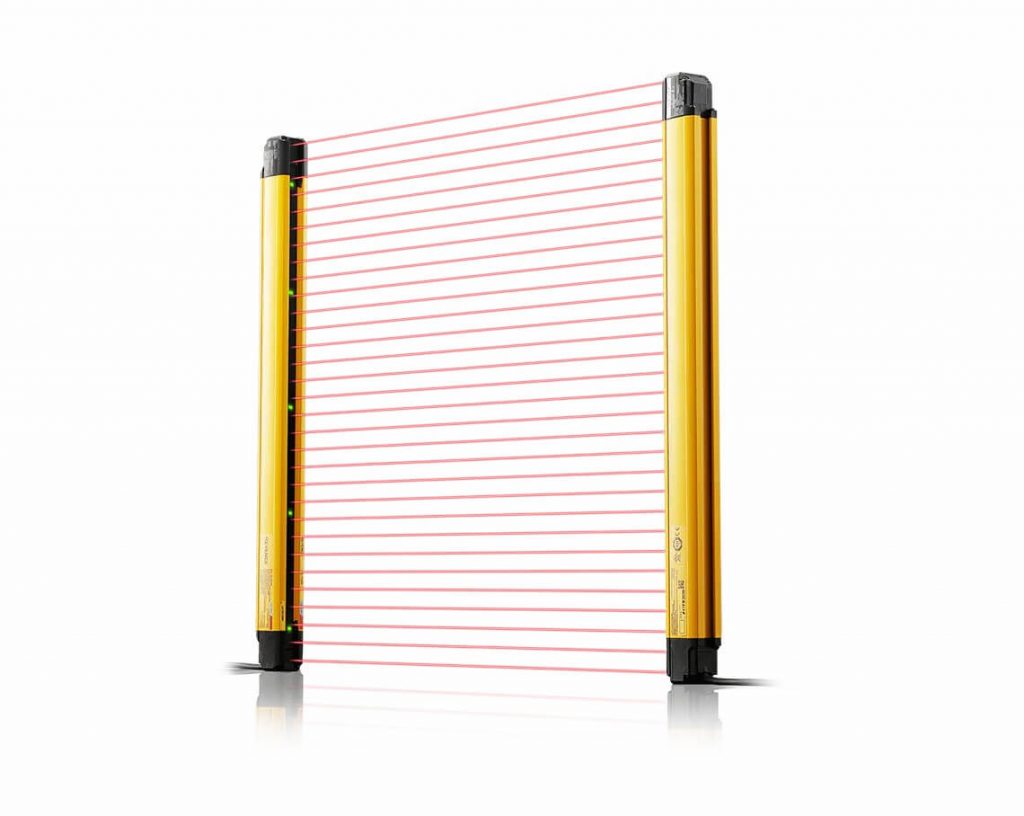

Safety light curtain is a device used to create a virtual barrier around hazardous environments. They are electrically operated and can be used as sensors to signal authorities and trigger emergency shutoff sequences to protect the personnel.

What is a Safety Light Curtain Sensor?

Safety light curtain sensors are devices used to create a ‘virtual barrier’ around a hazard. The area can contain fast-moving machines such as robotic arms or unguarded machinery.

These sensors provide a visible array of beams that provide a visual alert to the personnel while in use. If someone crosses through the beams, they generate a signal that can be used to trigger emergency shut-off of the hazardous machinery. Sometimes they are used to trigger alarms as well.

How do Safety Light Curtains work?

Safety light curtain sensors have two devices, placed parallel to each other. One is the emitter/transmitter unit and the other is the receiving unit. The transmitting unit consists of an array of LEDs or laser diodes (visible/invisible light). In some units, the LEDs are constantly lit up while others may have pulsating LEDs. The pulses are both sequenced and modulated. The sequence can be top-to-bottom or bottom-to-top. The LEDs are also turning on at a specified frequency.

The receiving unit consists of phototransistors/photodiodes and it is specially designed to detect the pulse pattern and frequency of the transmitter unit. The unit consists of a circuit that handles this task and it can differentiate its corresponding transmitter curtain unit from any other interference. This improves the noise and external interference immunity of the system.

Safety light curtains are available in many configurations. Some can detect any object passing through while others may be programmed/configured to not detect certain types of objects that are allowed to pass through. For example, a light curtain sensor installed on a conveyor can detect the objects being conveyed but can trigger when a larger or smaller object is detected.

These sensors can have integrated controllers, and provide a direct output such as a relay output or a PNP/NPN output directly connectable to a PLC or a load. More advanced sensor models have external safety control modules.

Safety light curtains also have built-in self-diagnostic functions. This makes them very well suited for safety applications rather than using a generic sensor like a photoelectric sensor.

What is a Safety Light Curtain used for?

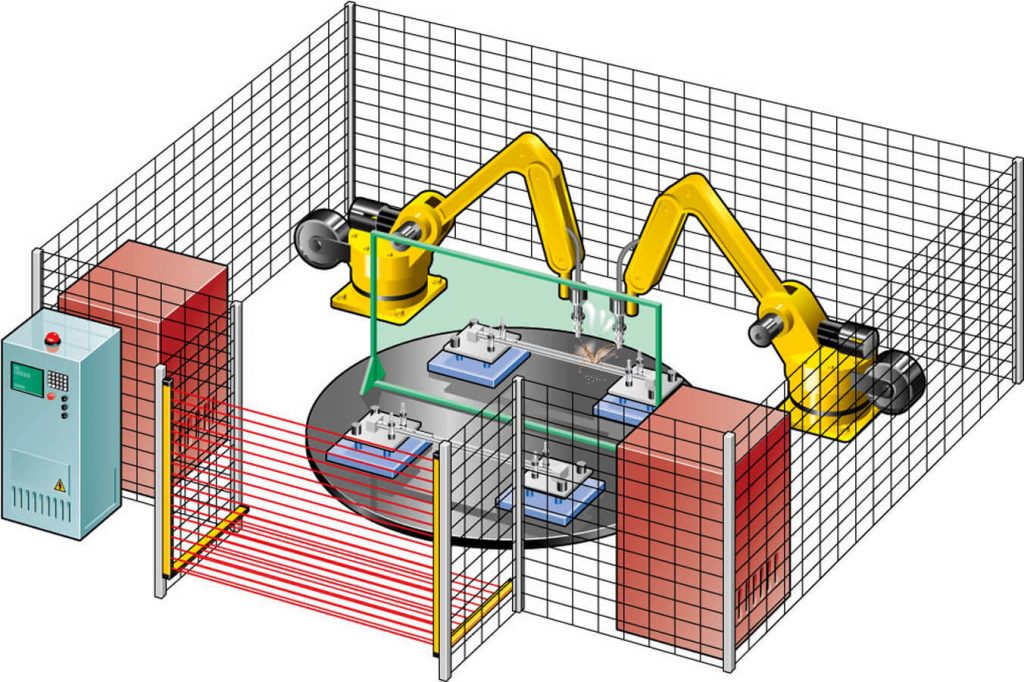

Safety light curtains are found in applications where the presence of human operators should be prohibited at certain instances. I.e. when the machine is in operation. For example, let’s look at the welding robot arm shown below.

The robotic arms are traveling at very high speeds and perform the welding operation. Before the machine starts to work, the operator must be able to enter the area, set up the part and perform the calibrations. Therefore using a physical fence is not an optimal solution.

When the machine is in operation, the access should be limited. If a person accidentally enters the area, the light curtain senses the movement and the machine immediately stops to prevent any accidents. This type of protection is called ‘perimeter protection’.

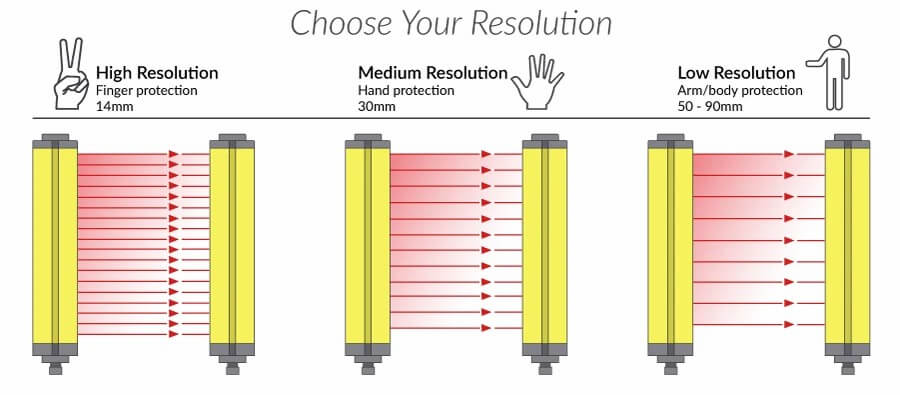

Another application is the ‘point of operation’ guarding. This includes assembly machines like hydraulic power press, molding press, eyelet, rivet and stamping machines. The application of a light curtain sensor is beneficial for the hand/finger protection of the operator while the machine is in use.

Benefits of Safety Light Curtains

- Safety light curtains provide additional protection like emergency shut-off and alarm triggering. This greatly improves the safety of the operator personnel and takes conventional methods like marking the area with hazardous signs to the next level.

- Most sensors are equipped with built-in self-diagnostics. They monitor the internal system for any faults and if a fault is detected, the sensor immediately sends a stop signal to the guarded machine. Once locked, the lock can only be released by repairing the sensor/addressing the issue or by performing the manual override reset.

- Safety light curtains conform to very high industrial safety standards like SIL3, PLe, and Type4 and are designed to be extremely reliable. Therefore, unlike using a simple photoelectric sensor, using a safety light curtain can greatly improve the safety compliance of the integrated system.

- Safety light curtains are designed to have maximum reliability and environmental resistance to ensure they can withstand pollutants and vibration in harsh environments.

Safety Light Curtain Types

There are two types of safety light curtains (SLCs):

- Point of Operation (POC) SLC

- POC light curtains are designed to protect a relatively smaller working area. This typically includes small machines like stampers, eyelet machines and similar which require an operator to be very close to the machine during operation. POC light curtains can protect the fingers, hands or arms of the operators.

- Perimeter Access Control (PAC) SLC:

- PAC light curtains are found where full-body protection is required. These can ensure that no person or object enters the protected premises.

These two types are purely categorized according to scale and size and both work the same way.

Other than the size/scale, SLCs also conform to industrial safety requirements like SIL(n) and Type(n), and Category(n). For example, There are SLCs that conform to Type2 and Type4 safety levels.

Depending on the risk level, Type4 devices check rigorously for faults within the device repetitively and autonomously. A Type2 sensor may only perform a fault detection check during startup. For high-risk applications, a Type4 light curtain will be more suitable where Type2 sensors will be used where a very small, yet existing risk is present.

Considering the accuracy and interference immunity, Type2 devices have a ±5 EAA (Effective Aperture Angle) whereas Type4 has ±2.5 degrees. This wider EAA makes the Type2 SLCs more susceptible to optical short circuits. Optical short circuit occurs when a highly reflective object deflects some or all of the sensing beams. The larger the EAA, the more susceptible a sensor is to optical short circuit.

Regardless of the type, category, and other characteristics, a SLC must comply with OSHA light curtain selection guidelines. Particularly, they must comply with IEC-61496 parts 1 & 2 adopted as ANSI/UL 61496 parts 1 & 2.

How do you choose safety light curtains?

When selecting a safety light curtain device for a particular application, a few key aspects need to be observed:

- Safety and Standards

According to the degree of protection offered, there are two categories of light curtains: Type 2, Type 4. Type 2 light curtains are suitable for low risk applications. They have a large field of view, and perform a self-diagnostic only during startup.

Type 4 is superior to Type 2 and suitable for low to high-risk applications/ They are used to guard personnel from access, point of operation and perimeters. Type 4 light scanners persistently check for faults and have the highest fault tolerance.

As per the standards, safety light curtains must conform with ASNI B11.19, IEC 61496, IEC/TS 62046 and ISO 13855.

- Performance

When selecting a suitable light curtain for a particular application, consider:

- Detection zone: Parallel, perpendicular or diagonal to the operator’s angle of approach

- Spanning Distance: distance between the transmitter and receiver

- Protection Height

- Controller: integrated PLC type or external controllers

- Sensitivity

- Environmental protection: the Ingress Protection (IP) rating of the device to work in harsh conditions

- Additional Features

- Floating beam mode: option to disable one or more beams at any location to allow movement through a particular section (automatically movable at a given rate)

- Self-checking circuits: the ability to diagnose and indicate any errors at startup or during operation

- Blanking/Banking: option to disable one or more stationary beams

- Latching safety relay: a special output that latches up when a person/object crosses the curtain and stays until deliberately reset.

- Muting: temporary bypass option to allow manual operation during non-hazardous operation of the machine

What are the safety standards for safety light curtains?

Safety light curtains must conform to the following standards:

- ASNI B11.19– Performance criteria for safeguarding

- IEC 61496– Electro-sensitive protective equipment

- IEC/TS 62046– Presence detecting equipment applications

- ISO 13855– Machinery safeguards for personnel

Conclusion

Safety Light Curtains are devices used to create a virtual barrier around a high-risk area. These sensors can sense an object or a person entering the hazardous area, and trigger safety mechanisms to reduce or completely eliminate the risk of hazard. In automation applications, light curtains are used to trigger emergency shut-off of machines to completely halt the machine before the operator comes into contact with it. In some applications, light curtains are used to count objects as well.