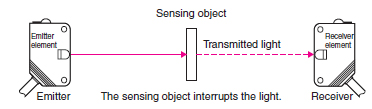

Through beam sensors, also the simplest type of photoelectric sensors. They are also called ‘opposed sensors’ due to their arrangement. The sensor consists of a transmitter and a receiver device, enclosed in separate housings.

In this article, let’s discuss what are through beam sensors, how they are made and their applications.

What is a Through Beam Photoelectric Sensor?

A through beam photoelectric sensor is a sensor that actuates an electrical switch/outputs a signal when a light beam is detected. They consist of two separate units, transmitter and receiver.

The transmitter unit emits a light beam aimed towards the receiver unit. When an object obstructs the light beam, the receiver detects the absence of the beam and triggers the output.

Through beam sensors find applications in applications such as counting items travelling down a conveyor line.

Through Beam Sensor Working Principle

Through beam sensors work in a very simple way. They make use of the rectilinear propagation property of light. This property describes that electromagnetic waves such as light tend to travel on a straight line in a homogenous medium.

There are two major components in a through beam optical sensor setup:

- Transmitter unit

- Receiver unit

Transmitter Unit

The transmitter unit consists of a light source, typically an LED which emits light in the visible spectrum. This unit also contains a lens setup to focus and direct the beam. To the naked eye, this would look like a laser beam.

Most of the transmitters only have the power wires. They can be turned on/off by supplying or removing power. Some sensors may have more than two wires, the additional wires are used to control the beam.

Some transmitters may emit a pulsating beam with a frequency of 500Hz.

These systems are more resistant to external interferences as the receiver works only with the pulsating beam.

Receiver Unit

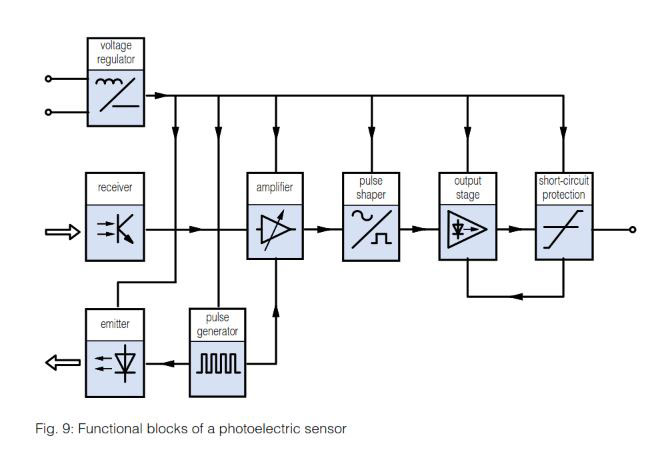

The receiver unit monitors the beam emitted by the transmitter. Similar to other types of optical sensors, a through-beam sensor has few key stages in its circuitry.

The figure below shows the functional block diagram for a through beam photoelectric sensor and transmitter.

- Voltage regulator

- The voltage regulator provides a clean power supply to the internal circuitry of the sensor.

- Photodiode and lens system (receiver)

- The lens system receives the beam and applies optical filtering and directs it onto the photodiode. The photodiode conducts current when the beam is focused onto its sensing face. This signal is amplified by an op-amp. The gain is adjustable using a potentiometer available on the sensor housing.

- Signal Conditioning Stage

- The amplified signal is filtered and matched with the receiving frequency. This allows the sensor to specifically monitor the transmitter’s beam and not be interrupted by an external light source. Any light beam that does not meet the system’s operating frequency criteria is filtered out at this stage.

- The conditioned signal is then passed through a schmitt trigger circuit that provides a clean control signal to the output stage to turn on/off the output.

- Output Stage

- The output stage consists of the electronics to control the output. Depending on the signal from the signal conditioning and filtering stage, this stage switches the output on/off.

- There are various types of output options available such as PNP, NPN transistor output and Normally Open/Normally Closed relay output. Most of the sensors available in the market have both NO/NC options.

Apart from the main blocks of the circuitry discussed above, industrial sensors have additional components to ensure the reliability of the sensor.

This includes reverse polarity protection diodes, over-voltage/surge protection and LED indicators to indicate the current status of the sensor.

Through Beam Sensor Application

Photoelectric sensors have many applications in industrial environments. Here are some where through beam photoelectric sensors are used.

- Object detection and counting in production lines or conveyors

- Mainly found in food processing and pharmaceutical industries, these sensors are used to detect the presence or absence of objects in all stages of processing. For example, a packing stage may use these sensors to accurately count a defined number of objects to be packaged.

- Security systems

- Through beam sensors can be used as a ‘tripwire’ mechanism to detect unwanted access to a secure area. If a person/animal crosses the beam, the signal can be used to trigger safety locks or generate an alert.

What Can a Through Beam Sensor Detect?

Through beam sensors are able to detect materials that are opaque such as wood, metal, plastic, diffused glass, mirrors and other solid objects.

Any object that does not allow light to pass through can be detected by the sensor. They can also be used to detect liquids for applications such as level sensing.

Through Beam Sensor Advantages and Disadvantages

Through beam sensors are well known for their superior operating range. Unlike many other sensors, they can operate from a few inches upto 300 meters apart from each other. This is due to the use of a single beam to operate.

This allows the sensor to use the highest optical energy level possible because the beam is not weakened by reflection.

These sensors can overcome conditions like lens contamination, hazy ambient air and slight misalignments.

There are some disadvantages in using through beam sensors as well. Since there are two separate transmitter and receiver units, the mounting process can be a bit difficult.

It may require two brackets for mounting and longer cabling to supply power to and transmit signals from the sensor.

Also, a through beam sensor may not be accurately able to detect a transparent object as the beam may leak through the object and illuminate the receiver.

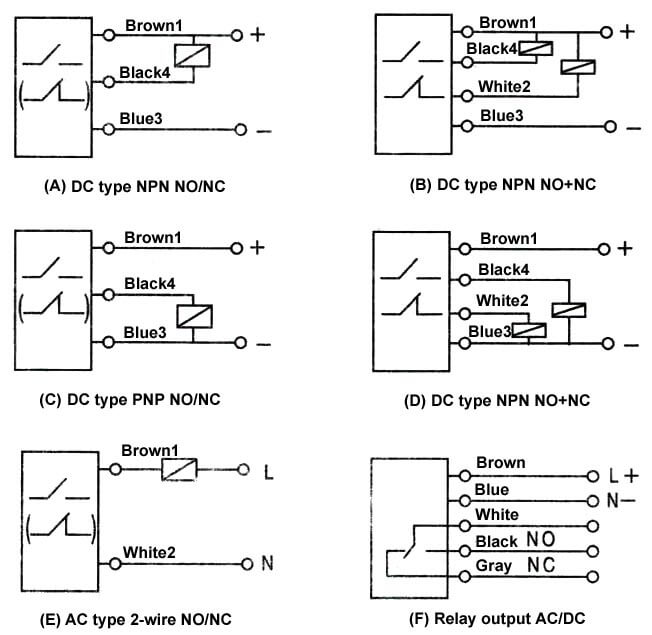

Through Beam Sensor Wiring

Through beam sensors are available in many different wiring combinations such as:

- DC NPN NO or NC

- DC PNP NO or NC

- DC NPN NO+NC

- AC 2-wire NO or NC

- Relay output AC/DC

The NO+NC type sensors are such that the normally open output and normally closed outputs are complementary to each other. Two separate loads can be connected to them.

It’s worth mentioning that the typical current a photoelectric sensor can handle is less than 400mA for a DC or AC type and less than 2A for a relay output type.

Therefore, connecting the sensor directly to a load such as a power relay or a contactor can damage the sensor when switching.

Through Beam Sensor Price

A through-beam sensor can cost from $30 to $150. The price varies due to the available features like,

- Configurable dark-on or light-on modes

- Range and sensitivity

- Output type

- Ingress Protection (IP rating)

There are some photoelectric sensors that are configurable to function as through-beam, diffused or a retro reflective type sensor. These sensors are typically more expensive than single-function sensors.

Conclusion

In this article, we looked at the construction of through beam photoelectric sensors, their working principle and applications. Through beam sensors have the highest sensing range among photoelectric sensors.

They are available in different sizes and shapes to fit almost any application. They can be an ideal for detection of opaque objects from a considerable distance.